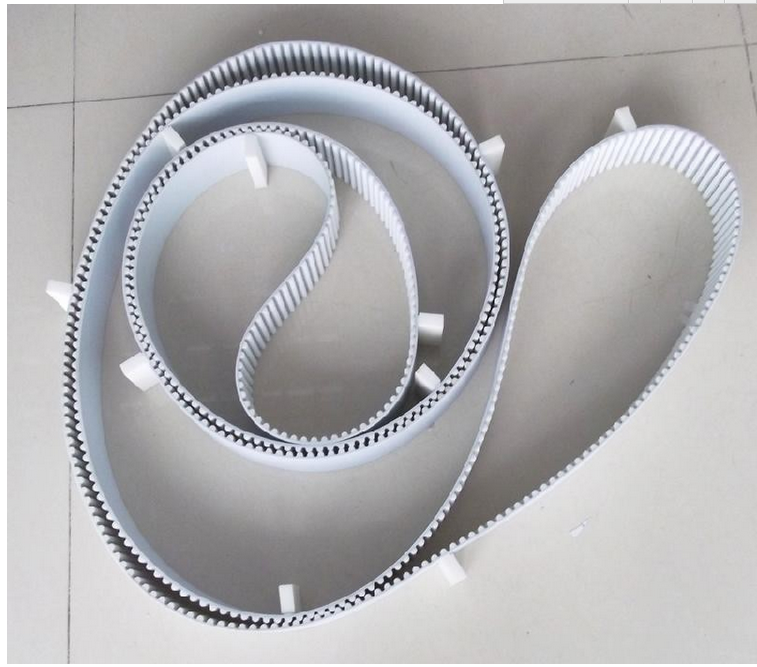

In order to maximize efficiency, mask manufacturers generally choose mask machines with high automation equipment, which will use a lot of industrial belts. Specifically, the following three kinds of belts will be used: 1. In terms of conveying, White PU conveyor belt, also known as mask machine baffle synchronous belt, is used. Baffle is processed on the belt surface, and the width of the belt is usually 11cm. 2. In terms of power transmission, light green / Green high-speed plane transmission belt is used, which is generally 2cm wide. 3. In terms of motor transmission, black rubber synchronous belt

Mask machine baffle synchronous belt is a non-standard customized synchronous belt. The base band adopts polyurethane synchronous belt in line with medical and health standards. It has the characteristics of accurate transmission ratio, oil resistance, wear resistance, aging resistance, good ozone resistance and strong tear resistance. The transmission efficiency can be as high as 98%. It is an ideal belt for conveying mask. How does the timing belt realize the function of accurately conveying masks? First, we will make a set of positioning molds according to the requirements of customers, and firmly weld the baffle on the surface of the synchronous belt through special processing equipment, or fix the baffle on the surface of the synchronous belt by threading screws, so as to achieve the effect of accurate delivery of masks.