Description

To determine the quality of a synchronous belt, you can consider the following aspects:

- Material quality: High-quality synchronous belts are typically made from premium materials such as high-strength polyester fibers or glass fiber reinforcement. These materials provide excellent wear resistance, tensile strength, and resistance to chemical corrosion.

- Structural design: The structural design of the synchronous belt directly affects its transmission efficiency and service life. A good synchronous belt should have a well-designed tooth profile, consistent tooth pitch, and reinforced tooth roots to ensure stable and reliable power transmission.

- Manufacturing process: High-quality synchronous belts are manufactured using precision manufacturing processes. This includes precise control of molding temperature, pressure, and time parameters to ensure consistent dimensional accuracy and surface smoothness.

- Durability testing: Evaluating the quality of a synchronous belt can be done through durability testing. Common test methods include tensile tests, torsion tests, fatigue life tests, etc., which simulate stress and environmental conditions under actual usage scenarios to assess the belt’s durability performance.

- Brand reputation: Choosing synchronous belts from reputable brands or manufacturers with a good reputation often provides a more reliable quality assurance. These brands usually have strict quality control systems and offer better product quality and technical support.

By considering these factors together, you can judge the quality of a synchronous belt and choose a high-quality product that suits your specific needs.

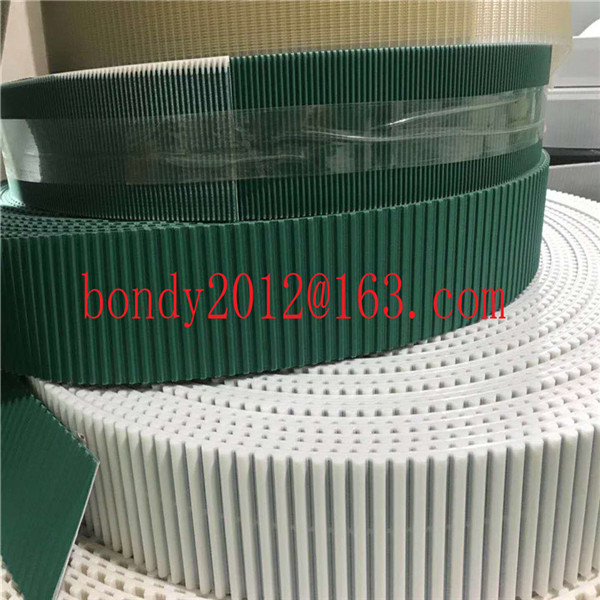

26T10-3040 PU TIMING BELT